In Memoriam:

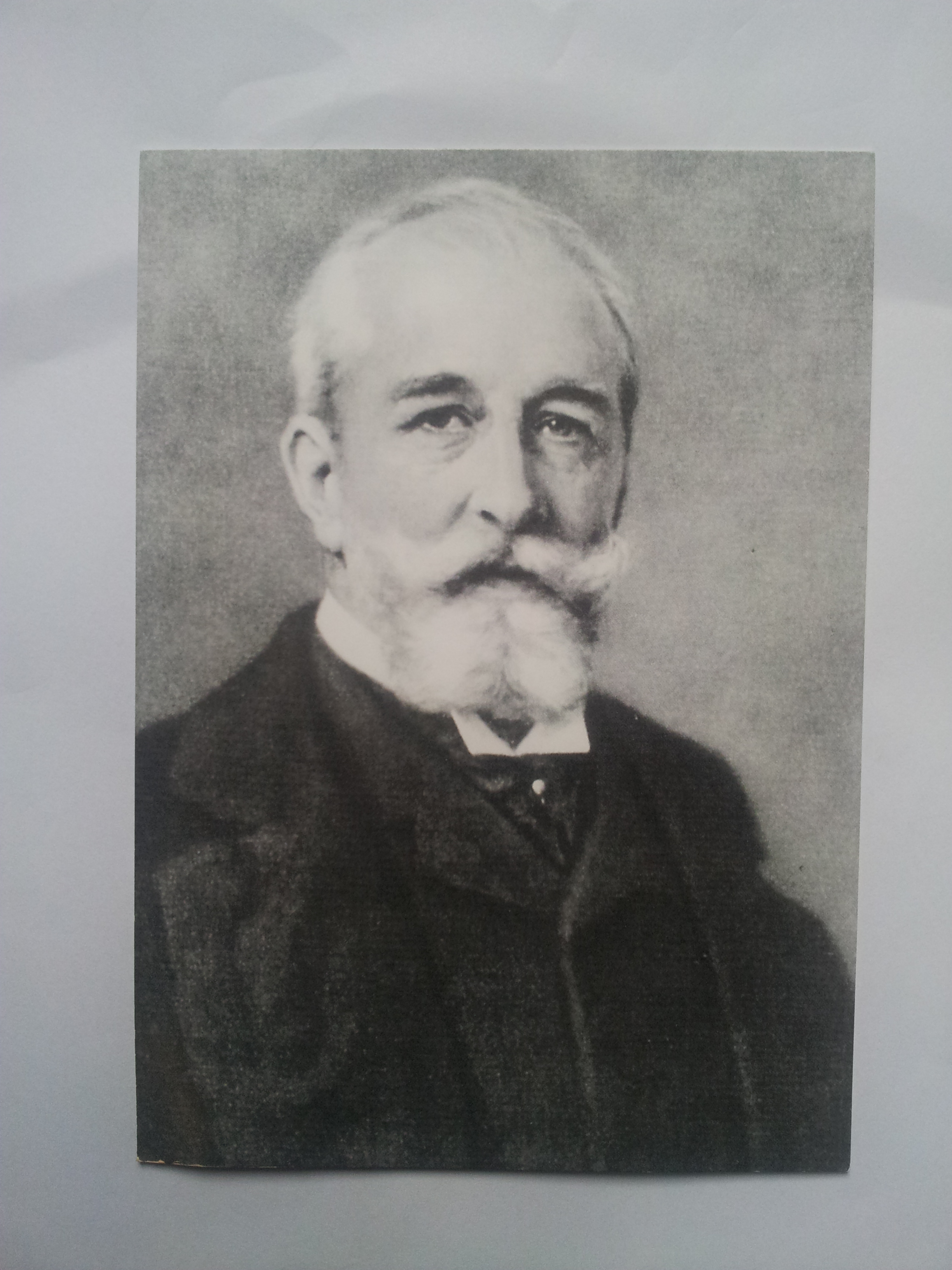

Franz Clouth (1838 - 1910)

und Nachfolger Max Clouth

Wagnis Arbeit

Freiheit im Denken und Handeln Erfolg

______________________________________________________________________________________________________

|

In Memoriam:

Franz Clouth (1838 - 1910)

und Nachfolger Max Clouth ______________________________________________________________________________________________________ |

|

Lenkbares Luftschiff Clouth

Clouth Firmen Logo

Tiefsee-Kabel

Altreifen Erste Militärballons

Bakelite Radio

Cöln Anfang 20 Jhdt.

Franz Julius Hubert Clouth 1862

Bronze Büste Franz Clouth

Franz Clouth 1905

Clouth Book 1st Edition

Tauchhelm Clouth

Altwappen Clouth

Clouth-Wappen 1923

Max Josef Wilhelm Clouth

Preisbild Ballonwettbewerb

Eugen Clouth

"Anni" Heine Clouth

Anni & Peter

Peter Rochus Clouth

Margot Clouth, geb. Krämer

Jürgen Clouth 12

Vettern Peter (l) & John (r)

Rechtsanwalt J.P. Clouth

Ehefrau Audrey Clouth 15.1.1950-22.11.2017

Bryan, Oliver, Phillip

Jürgen Peter Clouth

Max Clouth

Ballon Sirius Alpenquerung

Bakelite Verteilerfinger

Franz Clouth

Eugen Clouth

Clouth Werk

Clouth Werbung

Clouth Notgeld

Clouth Werk

Alt-Autoreifen

Altfahrzeug

Daimler

Förderbandkran

Clouth VIII Ballon

Wilhelm Clouth

Katharina Clouth

Caouchoc Golf Ball

Skizze Clouth Denkmal

Altkatholische Kirche Köln

Kabelaufroller

Clouth IX

Flugticket Clouth IX

Ballon Clouth IX über Alpen Post-Karte Franz Clouth

Clouth Buch 2.Ausgabe

Franz Clouth

Ballonkorb

Butzweilerhof Köln

Caouchoc Baum

Caouchoc Trocknung

Kautschuk-Kopier System

Wasser-Regulator Clouth

Land & See Altes Logo

Land & See NEULogo

Franz Clouth

Richard Clouth

Industrieverein Altlogo

Tauchergesellschaft LOGO

Halle Förderband Produktion

Firmentor 2

Bakelite Telefon

Podbielski Kabellegeschiff Kölner Ei Geräuschdämmung

Druckerei Wilhelm Clouth

Max Clouth ca.1950

engl. Laster Daimler

Daimler Bus

Ebonit-Telefon

Dampfmaschinen

Lampenfortschritt

Bekelit-Radio

KNG Senatspräsident J.Clouth

Juliane Heine/Hardware

Pfarrer W. Kestermann

Alt-Katholische Kirche Köln

Alte Alt-Kath. Kirche

Walzwerk für Gummi

Walzwerk 2

Guttapercha Pflanze

Tauffahrt Clouth VIII

Katharina Clouth

Alt-Katholische Kirche Köln

Ballonhalle

Flugobjekt-Wandel ab 1910

Charles Goodyear

Rubber Sheets

Clouth Förderband

Clouth Pentagon 1899

Audrey Clouth 2017

Rohkautschuk

Guttapercha Wäscher

Ballon Clouth VIII

Anni Heine-Clouth

LOGO Sternengasse

J.P. Clouth

Josefine Clouth

Ella Clouth

Altkatholische Kirche Köln

Köln

Cölner Dom

Golfballwerbung

Clouth Tauchhelm

Clouth Taucheranzug

|

Rechtsanwalt Jürgen Peter Eugen Franz Clouth 2016 Freedom of work, Freedom of thought and action Success

At the beginning of a company was in former time often only the honest effort of

an individual to prove itself in life.

Through an idea, through the environment, political incentives, or even by

chance, this search may someday be a direction and a goal, as far as the

political conditions permit this of course.

Founding years, as they were available to Franz Clouth at that time, we would

once again urgently need in Germany - a time of departure, progress, and

self-responsibility of the individual (CALVIN) as it existed before the widening

social state.

In the period from 1830 to 1900,

the "German industry", that, which still feeds us today, was successfully

developed in the post-war period of Germany through the politics of Prof. Dr.

Ludwig Erhard within the framework of ordo liberalism forced onto the post war

Germans by America and the UK successfully. A great deal of hope for

the entrepreneur would be the union of Europe if it succeeded to revive the

entrepreneurial liberties by defending a European central state in the direction

of a federal union and to protect it for every willing to venture. There is

already some evidence that the development of Community law and its interactions

with national law and laws, as well as the jurisprudence of EUGH (European

Court), would be considered in terms of liberalism. On the other hand, the

emigrating political activity of the Socialist International / ICOR in the area

of Europe makes the will to the European Communist central state, and thus to a

state preferred by Marx, clear. British voters and their government seem to feel

and foresee that already, one reason for BREXIT 2016? "Freedom of work, Freedom of thought and action Success!" J.P. Clouth (Lawyer & Merchant)

Clouth Firm Cologne 1873 In England and the USA, Macintosh, Hancock and Goodyear was able to process the natural product rubber technically, the first rubber factory was founded in Austria in 1828 and one year later the first German rubber factory was built in Finsterwalde near Berlin. After the beginning of the vulcanization technique from 1840, further works followed in Berlin in 1849 and in Hamburg in 1856. The well-known "Phoenix" rubber factory, 1862, was later developed from the Harburg Gummikamm Compagnie and Harburg Rubber Works Albert and Louis Cohen , When Franz Clouth founded his first company in the Kölner Sternengasse, Hanover 's Gummikamm - Compagnie, the germ cell of the later Continental, was established in Hanover.

Clouth Products sold world wide BRIEF HISTORY & INTRODUCTION OF RUBBER

Plantation Caouchoc Sheets

Rubber was known to the

indigenous peoples of the Americas long before the arrival of European explorers.

In 1525, Padre d'Anghieria reported that he had seen Mexican tribespeople

playing with elastic balls. The first scientific study of rubber was undertaken

by Charles de la Condamine, when he encountered it during his trip to Peru in

1735. A French engineer that Condamine met in Guiana, Fresnau studied rubber on

its home ground, reaching the conclusion that this was nothing more than a "type

of condensed resinous oil".

The capital of Amazonas State become the economic heart of Brazil. It was

equipped with water and electricity supplies, in addition to telephones and

large buildings such as the Amazonas Theater, still today a symbol of the wealth

brought in by Brazil's rubber boom. Thousands of immigrants flowed in, mainly

fleeing the drought that assailed Northeast

This ambitious project was soon christened Fordlândia by the local residents. It

was designed to produce 300,000 tons of natural rubber a year, accounting for

one half of global consumption. But the Ford Project succumbed to the hostile

environment of the Amazon rainforest and was abandoned, posting huge losses.

The importance of the rubber industry ever since it first appeared and the

decisive role that it has played in the development of modern civilization

prompted much interest in discovering its chemical composition in order to

synthesize this product. Through these research projects, the tire industry saw

the possibility of breaking away from the grip of the world's natural rubber

plantations.

This was how GR-S, Buna S, Hycar OS and SBR appeared, which are styrene and

butadiene copolymers.Friedrich

Hofmann, from 1897-1918 Chemist at the Elberfelder Farbenfabriken, former Bayer

& Co., developed the first synthetic rubber for which the Imperial Patent Office

granted patent no. 250 690 on September 12, 1909. The launch-pad for the massive development of the

synthetic rubber industry, this product could be vulcanized easily, and became

the flagship of the world rubber industry, although its properties did not

correspond to all the qualities of natural rubber. But its costs and main

characteristics made it into an unbeatable competitor. Although synthetic rubber

had been known since 1875, its production had been expensive and almost

negligible.

A wide variety of synthetic

rubbers have been developed since this product was first discovered. As massive

investments were required to develop these different varieties, the production

technology was heavily concentrated in long-established global enterprises such

as DuPont, Bayer, Shell, Basf, Goodyear, Firestone, Michelin, EniChem, Dow, and

Exxon.

Rubber Sheets How did it get to Franz Clouth?

as a young entrepreneur about 1873,

about 1908

app. 1890 He had recognized the importance of the rubber industry in the Rhineland, and gained considerable experience through visits to England. Early on he received awards at exhibitions. In 1868 the resettlement began on the still existing factory site in Nippes. This was carried out with his own funds and with the financial support of his brother-in-law, the Cologne shipkeeper Karl Wahlenberg. The site was from the start to a later expansion. This also from the point of view that from the very beginning Franz Clouth intended to deliver exclusively to industry, that is, in large volumes. Franz Clouth was not the first rubber factory in Nippes. Before him, Ferdinand Kohlstadt had been relocated to Nippes for the production of rubber bands from Cologne, and moved to Deutz in 1864. During the Franco-Prussian War of 1870-1871, Franz Clouth, though not a member of the army, was a military member. He succeeded several times in bringing railroad trains with so-called love gifts for the soldiers to the gates of Paris. At the same time, he sold imported rubberized materials from England to the German siege armies before Metz and Paris, as his son Max later reported. The company had the greatest success at this time, however, with Franz Clouth's patented copy sheets, the "Franz Clouth's unbelievable Caoutchuc copiers," which were successful in the market until the introduction of copying machines. In 1873 began the production of rubber roller covers. Between 1872 and 1875, 200 people worked at Clouth. Besides the already mentioned copying leaves, milk bottle suckers, erasers and, from 1881 on, the Tourniquet hosiery, which could also be used as an assembly tool. After lengthy negotiations with the inventor, the surgeon at the University of Kiel and the real secretary of Frederick of Esmarch, 10 pfennigs were donated for every "Samariterzwecke". In total, 30,000 marks came together. At the same time, the company also distributed rubber articles from other manufacturers from Germany, France and especially from England. In 1875 Clouth was the first to erect a department for the production of soft rubber in Germany. The later production consisted of rubber belts, driving ropes and conveyor belts, as well as rubber covers for rollers. This product range has attracted more and more customers in the booming industry, especially in the mining, armaments and colonial sectors. Lu-xusdampfer and D-trains were equipped with flooring from Clouth. Clouth products have already been delivered to Belgium, the Netherlands and Switzerland. The entire demand for milk bottle cleaners in Germany, Holland and Switzerland was at present covered by Clouth. With the further expansion of the sales markets it was already said that Franz Clouth had practically a world monopoly on these goods.

In the municipal election on 28 and 29 December 1885, Franz Clouth was elected to the municipal council of Nippes. In the decision of the Nippeser municipal council of 2 August 1887 of the incorporation to Cologne, Franz Clouth was thus decisively involved.

After negotiations between Felten & Guilleaume and Clouth had failed in 1890 for the purpose of mutual supply, Felten & Guilleaume founded its own rubber factory and Clouth established its own cable manufacturing under the name "gutta-percha-insulated wires and cables". Clouth was appointed by the competing companies Siemens & Halske in Berlin and Siemens Brothers in London. Said companies complained. And a patent filed by Clouth. The trial ended in 1893 in favor of Franz Clouth. About 1890, Clouth was also one of the first rubber manufacturers to set up his own laboratory. He had realized that one can not do without scientific work in an industrial enterprise. The laboratory should therefore be used for research, in particular for quality assurance. Many reports show that Franz Clouth had already tried very early to prevent complaints or at least to minimize them. Under the responsibility of their own cable production, Land- und Seekabelwerke AG was founded on May 11, 1898, in which Franz Clouth was a 50% shareholder. The other 50% held Berlin and Cologne banks. Of the land & sea cable plants founded by Clouth, the first remote cable from Emden to New York was laid. Because of the high demand, a cable ship was bought by Franz Clouth in England, if via Lord William George Armstrong, Newcastle, is not yet cleared.

Through the mediation of the

Reichspost Felten & Guilleaume renounced the construction of a separate plant in

Emden and Under the direction of Franz Clouth, the "Verein der deutschen Kautschukwarenfabriken" (Association of German Rubber Warriors) was founded in Berlin in 1895. He was a member of the "Central Association of German Industrialists" and the "Association for the Protection of the Interests of the Chemical Industry", a member of the "Verein for the Protection of Common Economic Interests for Rhineland and Westphalia". As a member of the board, he belonged to the "Verein der Industriellen des Regierungsbezirkes Cöln" and the "Rheinische Dampfkessel-Überwachungsverein", today's German TÜV (technical MOT). He had cofounded both clubs. In the "Verein der Industriellen" ("Association of Industrialists"), he concentrated mainly on matters relating to occupational health and safety and smoking incineration regulations, as well as on the development of the Nippes region and the economic development of Cologne. Because of an indiscretion, he resigned as a member of the board in 1904, but was reelected two years later. With these activities "around the rubber" it is astonishing that Franz Clouth is not bigger in the production of car tires. As early as 1882, the company produced Vollgummireifen for electric carts and tubing for automobile tires. In a magazine in 1899, she had advertised her "best" tires for Automobile. A legend reports that he ultimately had not believed in a success of the Automobile and thus the car tire. But this alleged statement by Franz Clouth is nowhere recorded.

Franz Clouth also had recognized the importance of cable production and laying in the context of the economic debate with England and German colonialism and acted accordingly. Clouth made the most successful deals with the laying of cables to the then German colonies. It is therefore no wonder that Franz Clouth supported the colonial efforts of the German imperial empire. He was a co-founder or a member of the Supervisory Board at the German Atlantic Telegraph Company, the Telegraph Company in Eastern Europe, the German-Dutch Telegraph Company, the German-South American Telegraph Company and the Kabelwerke Aktiengesellschaft Felten & Guilleaume in St. Petersburg . He was in a correspondence with some of the German colonial travelers. Another profit-making field was the armaments industry. For the imperial navy, Clouth developed and built its own diving apparatus with hearing and speech connections as well as airbags for the recovery of sunken ships. As already stated, the company became a monopolist in 1887 for dive machines of the imperial navy. At the regatta on 7. In June 1914, the yacht Meteor won the title of Emperor Wilhelm II and received as a trophy a gold-plated diving helmet, which the company Clouth had donated. Through an exhibition on the imperial yacht Hohenzollern and the Berlin castle, the helmet got into the possession of the Imperial Yacht Club in Kiel in 1926. In 1937 Director Print-miller managed to get him back for the Clouth Museum. For the armies of the German states Clouth made watertight tents and pumps. The imperial air force ordered protective covers for the propellers of their machines

In 1902 a rubber belt was shown at the industrial exhibition in Dusseldorf, which had already been in operation in a coke oven plant for 20 years and had only been extended for the exhibition. In the same year, Clouth maintained its own offices in Berlin, Hamburg, Brussels, London and Paris. Max Clouth himself directed the Paris and London offices for several years. A book by Franz, Clouth, "Gummi, Guttapercha und Balata" was published in English in 1903 in London and New York, and had long been regarded as the standard work of the rubber industry in both countries. During his visit to the USA in 1927, Max Clouth was repeatedly asked whether he was related to the author of this work. In 1907, the good experiences described in Saxony with sealing rings for Water and gas pipelines, which after 10 years still showed their full elasticity.

Old Catholic "Franz Clouth", church of England in close connection In 1869 Pope Pius IX convened a "general" church meeting in the Vatican. It is true that the Pope only ruled in the Roman Catholic Church, but he regarded it just as the "general" church and its special assemblies for equal importance in word and dignity to the great church assembly of Christian antiquity Later sense. Simultaneously with the convocation of the Vatican Council, the rumor spread that the doctrines of the episcopal omnipotence and the infallibility of the pope for divinely revealed beliefs were to be explained. These teachings show that the Roman pope possesses the full abundance of the highest, orderly and immediate, truly episcopal power, not only in matters of faith and morals, but also in matters of discipline and government over the entire world, in other words That he was the only true bishop of the Catholic Church, and that all the bishops were only his deputy; And further: that a decision made by the Pope concerning a doctrine of faith and morality should be infallible, infallible, and in itself, not by the consent of the Church.

These views were not entirely new in the Catholic Church, inasmuch as in the

Middle Ages similar claims were raised from the papal side, and in modern times,

especially the Jesuits endeavored to spread them;

Already at the church meeting in Trento (1545-1563), which had a large

settlement with the Reformation, had tried in vain to bring them to recognition.

In the meantime, this church church recognition had not yet been attained;

It should now be done.

Like a man, all the Catholics, who felt free and German, rose against this

purpose, for with these beliefs their whole ecclesiastical existence was

questioned. Thus it is comprehensible that all the religious forces that were alive in the Catholic Church had come together in the struggle against the Vatican endeavors, even if there had been no relations between them before. The whole general public turned their attention to this struggle, for at that time the Catholics were still active in all political camps, and took part in all general endeavors in scientific, artistic, and social fields; It was not yet as it was today, for Ultramontanism had not yet held its triumph, drawing its path with denominational parties, universities, associations, trade unions, bathing beaches, and dancing. All the efforts of bishops and theologians from different countries to defend their doom were unsuccessful: on the 18th of July, 1870, the new faiths were proclaimed as "divine revelation"; 533 members of the church assembly agreed. But they did not represent any part of the church; Because they were only titular bishops or the like, 77 represented the church in the most recently converted parts of America, and Australia, many other areas of mission, And another figure represented very small dioceses. 250 had previously not, however, declared themselves against it; 35 million believers and just the old parts of the Church were represented, while 25 million believers were still in the process of being represented. More than half of all Catholics were therefore uninvolved in the proclamation of these teachings. The German bishops had for the most part endeavored to prevent the proclamation of the faiths; But once the proclamation had taken place, they soon brought their conscience to rest, and now demanded their priests and faithful to accept and acknowledge these beliefs, but from meetings, books, pamphlets, and newspapers, they sounded 1000 times "no". Of course, there could be no question of a unified movement, which was not the contradiction of a particular ecclesiastical tendency or party, but rather the rebellion of the whole true Catholicism; There were so-called "old-Catholic associations" in Baden, who had endeavored to cultivate German consciousness in Catholicism since the days of the Syllabus, as well as "Catholic associations for the defense of the villian innovations" which had arisen in the emergency of the moment; The luminaries of science stood with their pupils and followers, and beside them the heroic peasant chaplain, Thomas Braun, who had fought against a world for the old Catholic truth since the proclamation of the Immaculate Conception of Mary, and under pathetic police attacks in Lower Bavaria Had suffered. At one stroke, however, the movement had a center, as the respected Catholic scholar of the day, the penitent, and university professor Dr. Ignatz von Döllinger in Munich, frankly and publicly, the new doctrines "as a Christian, as a theologian, as a historian, as a citizen." And was able to endure this attitude courageously and firmly, even when he finally had to take over the Church. Thousands of letters of approval and explanations flowed together; The university teachers had become the leaders. They gathered together fellow-men; In repeated discussions here and there they had gained touch; Munich, Bonn and Breslau were their headquarters. The clearest among these were the Prague Church Law Teacher Dr. Johannes Friedrich von Schulte. In September 1871, the first Old Catholics' Congress met in Munich. In the meantime, all the leaders had fallen into the hands of the church, the faithful threatened the same fate as soon as they became aware of their conviction. The hesitant wished to endure it, and to keep it all at the repeated appeal; It was with others, especially from Schulte, who decided to take self-help and collect their own congregations, that the break with the Roman church, founded on 18 July 1870, had been completed and a new home was created for the old Catholic Church. The Old Catholic Church, on the other hand, separated itself externally from the Roman, on the eighteenth of July, 1870, with the dogmatic explanation of the episcopal omnipotence and the doctrinal infallibility of the pope, the return to the ground of the old ecclesiastical Catholic doctrine Made it impossible for ever, had left the wide circle in her before.

A second Old Catholics Congress in Cologne in 1872 created a preliminary order

for the church life and made the preparations for the election of a bishop;

On June 4, 1873, a meeting of 21 priests and 56 lay deputies of the communities

which had been established elected the professor of the church history at the

University of Breslau, Dr. Joseph Hubert Rheinkens as the first bishop;

On May 27, 1874, the first synod, by unanimous acceptance of a "synodal and

church order," prepared by a third congress, held in Constance, in 1873,

restored the old church constitution to the young church system. This type of financing allowed the planned construction to be compiled relatively quickly according to the model developed. At the same time, however, the financiers in the strictly Catholic faithful of Cologne came to the rear of the building, for businessmen who at any rate were active in the region, a dubious venture, but less harmful to businessmen like Franz Clouth. This will have been different in private life, where parts of the family, kinship, neighborhood, population will have been kept back as far as possible.The construction of the building was not a hindrance, as you can see

The Second World War brought with it considerable damage, since the church was located directly on the railway line, which had several routes and therefore made possible military transports, so that this area was primarily considered for the bomb dropping The Campanile, the tower, and the functioning.

More on page "Old Catholics"

Rheinbreitbach Clouths |

|

Senden Sie E-Mail

mit Fragen oder Kommentaren zu dieser Website an:

clouth@bigfoot.com

mit Fragen oder Kommentaren zu dieser Website.

|